Durawell PVC Edge Banding Excellence

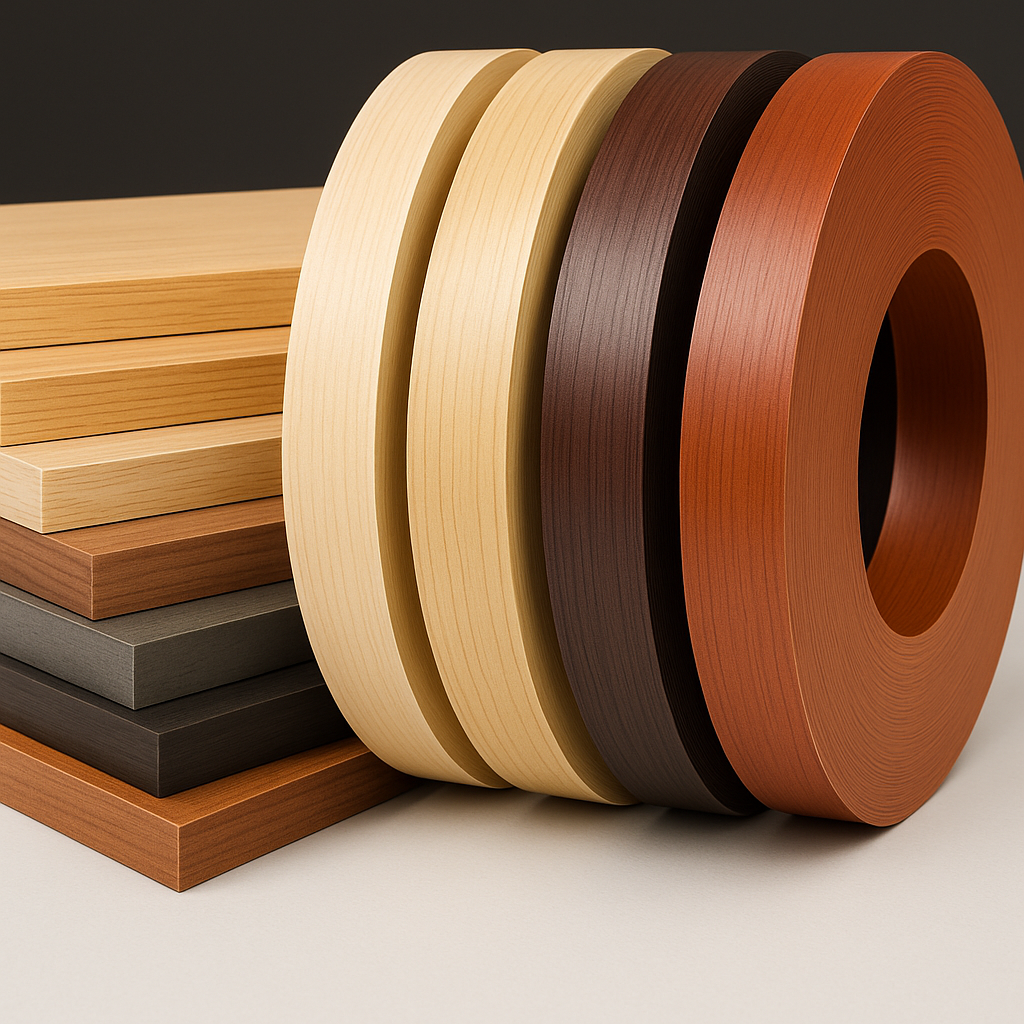

Durawell is a leading PVC Edge Banding Tape Manufacturer in India, crafting superior quality edge banding solutions with advanced manufacturing technology and strict quality control. Our tapes ensure seamless finishes, superior adhesion, and long-lasting performance, making them ideal for furniture and interior applications.

Available in various colors, textures, and thicknesses, our edge banding tapes perfectly match different laminate designs with precision. Whether for commercial or residential use, Durawell provides reliable and cost-effective solutions.

Product Information

Explore our product details, applications, and specifications

Superior Durability

Crafted for long-lasting performance, ensuring resistance to wear and tear even in high-traffic areas.

Thermal Stability

Designed to withstand high temperatures, maintaining form and function in extreme conditions.

Excellent Adhesion

Offers superior bonding capabilities, sticking seamlessly to various surfaces for a strong hold.

Ease of Application

Quick and hassle-free installation makes our edge banding tape ideal for any project, big or small.

Aesthetic Versatility

Available in diverse styles, colors, and finishes to enhance the look of any furniture design.

UV Resistance

Resistant to fading from sunlight, retaining its color and finish even when exposed to UV rays.

Standard Sizes

| Thickness | Width | Roll Length | Shade Range | Finish |

|---|---|---|---|---|

| 0.45mm | 22mm, 25mm, 30mm, 45mm | 25 Meters, 50 Meters | Solid, Wooden, Metallic, Fabric, Marble & Stones | Super Matt, High Gloss, Sparkless, Soft Touch & Acrylic (Only in 1.3mm) |

| 0.8mm | 22mm, 25mm, 30mm, 45mm | 25 Meters, 50 Meters | ||

| 1.3mm | 22mm, 25mm, 30mm, 45mm | 25 Meters, 50 Meters | ||

| 2mm | 22mm | 25 Meters, 50 Meters |

Note: Roll Length can be customized for bulk orders.

Technical Properties

| Description | Unit | Value | Standard |

|---|---|---|---|

| Hardness Shone | - | D-78± 4 | ISO 868 |

| Shrinkage (1h at 140°F [60°C]) | % | <0.5< /td> | Work Stand |

| Static Charging | - | Low | - |

| Vicat Softening Temperature (At 50N) | °C | 80.3 | ASTM D1525-2009 |

| Colour Fastness to Rubbing (Dry Staining) | Rating | 4/5 | IS:766-1988 |

| Colour Fastness to Rubbing (Wet Staining) | Rating | 4/5 | IS:766-1988 |

| Colour Fastness to Light (Type of lamp UV A340) | - | No Cracks or Blister Observed | ASTN G1 54-2016 |

| Colour Fastness to Light (Exposure Time 24 Hour) | - | No Cracks or Blister Observed | ASTN G1 54-2016 |

| Gloss Value (60°) | GU | 12-15 (Matt), 85-90 (Glossy) | ASTM D523-2014 |

| Heat Resistance | °C | up to 80 | Work Stand |

| Chemical Resistance | - | Good | DIN 68861 |

All specifications are tested under controlled laboratory conditions and may vary in real-world applications.

Application Guidelines

| Parameter | Recommended Value | Notes |

|---|---|---|

| Application Temperature | 180-200°C | For optimal adhesion |

| Feed Rate | 4-6 m/min | Depends on machine capability |

| Pressure | 3-5 kg/cm² | May vary with surface type |

| Storage Conditions | 10-25°C, 40-60% RH | Avoid direct sunlight |

Ready to Enhance Your Furniture?

Contact us today for customized solutions, bulk orders, and expert advice on choosing the right edge banding for your project.